Boost Your CNC Productivity & Profits with All CNC Sales & Service

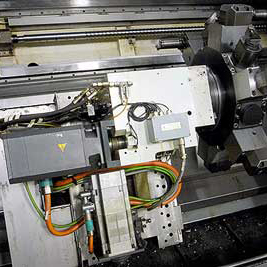

Providing CNC machining repairs, service, spare parts and more. We are also the leading reseller of Rotoclear the spinning window for CNC machines that allows for a clearer picture into the milling and turning process.

Don't struggle with in-house repairs – get expert CNC service & keep your machines humming.

Elevate your CNC machining with expert services and cutting-edge solutions

At All CNC Sales & Service, we're more than just a supplier – we're your trusted partner in achieving precision, efficiency, and profitability in your CNC machining operations. We offer a comprehensive range of solutions to empower you at every stage, from selecting the right equipment to optimizing your workflow.

Unleash the full potential of your CNC machines:

- Sales & Service: Our knowledgeable team guides you through selecting the perfect parts for your needs, budget, and desired capabilities. We also provide reliable maintenance and repair services to keep your machines running smoothly, minimizing downtime and maximizing productivity.

- Rotoclear Advantage: Gain unparalleled visibility into your machining process with our revolutionary Rotoclear spinning windows. These innovative systems, paired with optional 4K camera setups, offer real-time insights, enhancing safety, accuracy, and operator control.

- Expert Training & Support: Equip your team with the knowledge and skills to operate and maintain your CNC machines effectively. We offer comprehensive training programs tailored to your specific needs, ensuring optimal performance and minimizing waste.

- Consulting Expertise: Leverage our extensive industry experience to optimize your entire CNC workflow. We provide valuable insights on process improvement, tool selection, automation integration, and more, helping you streamline operations and boost profitability.

We are committed to providing our customers with the best possible service and support. We understand that CNC machines are an essential part of your CNC machining shop, and we are here to help you to get the most out of them.

About Us

We have been providing this service for over 40 years, and our team of certified technicians is highly skilled and experienced. We are committed to providing prompt and reliable service, as well as OEM spare parts and Repairs from OEM Products like Spindle, Turrets and so on.

If you are looking for a reliable and experienced CNC service provider, then ALL CNC is the right choice for you. Contact us today for a free consultation.

Why Choose Our CNC Solutions?

- One-stop shop: We cater to all your CNC needs under one roof, saving you time and hassle.

- Unwavering commitment: We prioritize your success and go the extra mile to ensure your satisfaction.

- Technical expertise: Our team boasts extensive knowledge and experience in all aspects of CNC machining.

- Cutting-edge solutions: We constantly seek out and implement the latest advancements in CNC technology.

- Dedicated support: We're always here to answer your questions and provide expert guidance.

Review just some of our case studies:

How ALL CNC Training Helped a CNC Manufacturer to Improve the Quality of Their Products

A CNC manufacturer was struggling to improve the quality of their products. They were experiencing a high rate of rejects.

The manufacturer enrolled their employees in CNC training courses. The training courses taught the employees how to operate CNC machines more effectively and how to identify and fix quality problems.

After completing the training courses, the employees were able to operate CNC machines more effectively and identify and fix quality problems. This resulted in a significant improvement in the quality of the manufacturer's products.

How Rotoclear Spinning Windows Helped a CNC Manufacturer to Improve Their Productivity by 10%

A CNC manufacturer was struggling to improve their productivity. They were experiencing frequent downtime due to machine breakdowns. The problem was that they were unable to see what was happening inside their machines, which made it difficult to diagnose and fix problems.

The manufacturer installed Rotoclear spinning windows on their CNC machines. The Rotoclear windows provided them with a clear view of the inside of their machines, even in the harshest conditions. This allowed them to quickly identify and fix problems, which reduced downtime and improved productivity by 10%.

How a 4K Camera System Helped a CNC Manufacturer to Reduce Cycle Times by 5%

A CNC manufacturer was struggling to reduce cycle times. They were experiencing frequent delays due to machine setup and troubleshooting. The manufacturer installed a 4K camera system on their CNC machines. The 4K camera system allowed them to monitor the inside of their machines and identify any potential problems early on. This allowed them to make adjustments to their machine setup and troubleshooting procedures, which reduced cycle times by 5%.

How Rotoclear Spinning Windows Helped a CNC Manufacturer to Extend Tool Life by 15%

A CNC manufacturer was struggling to reduce cycle times. They were experiencing frequent delays due to machine setup and troubleshooting.

The manufacturer installed a 4K camera system on their CNC machines. The 4K camera system allowed them to monitor the inside of their machines and identify any potential problems early on. This allowed them to make adjustments to their machine setup and troubleshooting procedures, which reduced cycle times by 5%.

Contact Us

Please don’t hesitate to contact us for more information